Polyurethane Glue for Aluminum Composite Panel and Sandwich Stucture Bonding (Flexibond 8211)

Basic Info

Model No.: Flexibond 8211

Product Description

Model NO.: Flexibond 8211

Morphology: Solvent Free

Material: Polyurethane

Characteristic: High Adhesion Strength

Size: 24kg+6kg Barrel

Transport Package: Resin: 24kg/Barrel Hardener: 6kg/Barrel

Origin: China

Bonding Function: Structural Adhesive

Application: Building Materials

Classification: Room Curing and Thermosetting

Color: White

Trademark: Flexibond

Specification: ISO9001, ISO14001

Description

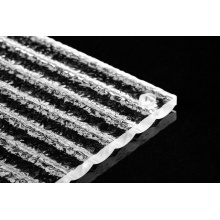

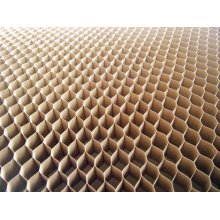

Flexibond 8211/Flexibond 8200 is a two-component Polyurethane Adhesive which is applied for structural bonding for various substrates, such as aluminum honeycomb, wood, PU foam, polystyrene foam board, glass fiber-reinforced plastic, aluminum plate and steel plate, etc.

Characteristics

(1) Excellent adhesion to various substrates.

(2) Cures fast, shortens heat or cold setting time.

(3) Solvent free, environmental friendly.

(4) Good humidity and heat resistance.

Application

(1) Adhesive Coating:

The recommended dosage is 200-400G/M2. The dosage varies with the roughness of the substrate surface.

(2) Mixing Ratio

Flexibond 8211/Flexibond 8200=4: 1 (by weight)

The resin (8211) should be uniformly stirred before it is mixed with the hardener (8200). Mix the two components uniformly. Mix for 1-2 more minutes after the two components color is well mixed.

(3) Adhesive Coating Temperature:

The adhesion should be taken within its open time. The open time and curing speed will be affected if the temperature is too high or too low.

(4) Pressing:

Raise the pressing pressure as high as possible without affecting the material forming.

(5) Pressing time

The pressing time is 6-8 hours. The adhesive is fully cured in 7 days. The higher the temperature is, the faster the curing is. The pressing time can reach 30 mins under the temperature of 80.

(6) Clean

Recommended Cleaner: Acetone, butanone.

Packaging

Resin: 24kg/barrel

Hardener: 6kg/barrel

The packaging can be adjusted according to customer's requirement.

| | Flexibond 8211 (Resin) | Flexibond 8200 (Hardener) |

| Curing mechanism | Poly addition | |

| Chemical base | Multiplehydroxyl compound | PAPI |

| Color | White | Brown |

| The coloraftermixing | Light yellow | |

| Density (beforecuring) | 1.50±0.05g/cm3 | 1.2±0.05g/cm3 |

| Viscosity | 15000-20000mpa.s | 250mpa.s |

| Viscosity (aftermixing) | 8000-12000mpa.s | |

| Mixingratio (by weight) | 4 | 1 |

| Pot life (23c) | 30-50mins | |

| Open time (23c, 50%RH) | 50-70mins | |

| HardnessshoreD (GB/T 531-2008) | Approx 75 | |

| Shear strength (GB/T 7124-2008) | ≥12Mpa (Aluminum alloy) | |

| Flat tensile strength (GB/T 1452-2005) | ≥1.5Mpa | |

| Climbing drum peel strength (GB/T 1457-2005) | ≥80N@mm/mm | |

| Shelflife (unopened below 25c) | 12months | 6months |

Contact us if you need more details on Polyurethane Adhesive. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Polyurethane Glue、Solvent Free. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Pu Adhesive For Furniture And Building Materials

Premium Related Products

Other Products

Hot Products

Multiple Purpose Neutral Sealing High Grade Neutral Silicone SealantCsj-613 Silicone Sealant for Stone C-891 Sanitary SealantTwo Components Silicon Sealant for Insulating Glass Seal and JointHigh Quality Stone Silicone SealantAcetic General Purpose Silicone SealantExcellent Silicone Sealant with Competitive PriceNo Pollution Granite Silicone SealantOne Component Quick Curing Silicone SealantAnti-Mildew Sealant for Kitchen & Bathroom (C-891)Acetoxy Silicone Sealant for General Purpose C-363Two-Component Silicone Sealant for Insulating GlassHigh Performance Weatherproof Silicone Sealant for PVC Skylight CanopyStructural Silicone Sealant for Aluminum Composite PanelsFast Curing Structural Silicone Sealant for Glass Fish TankFast Curing Neutral Silicone Sealant for a Wide Range of Aluminum Doors and Windows